Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

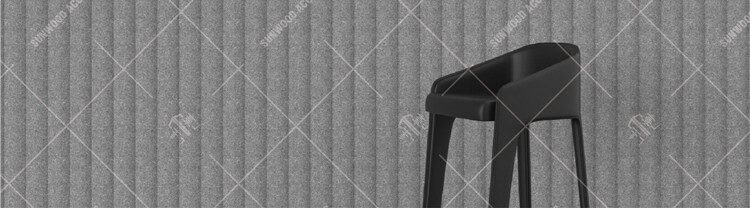

Thermal Forming PET Acoustic Panel

PRODUCT DESCRIPTION

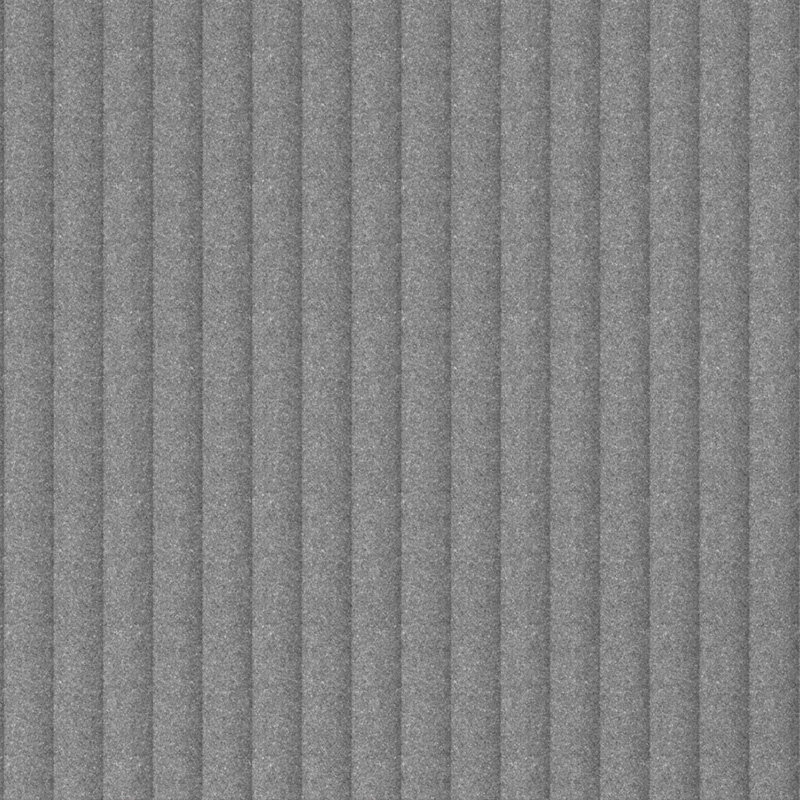

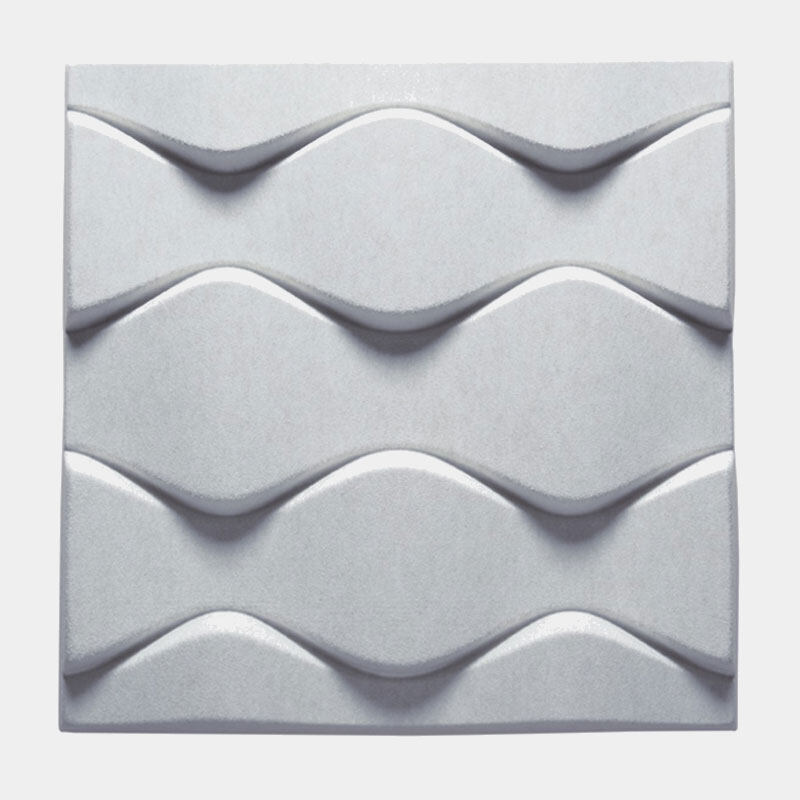

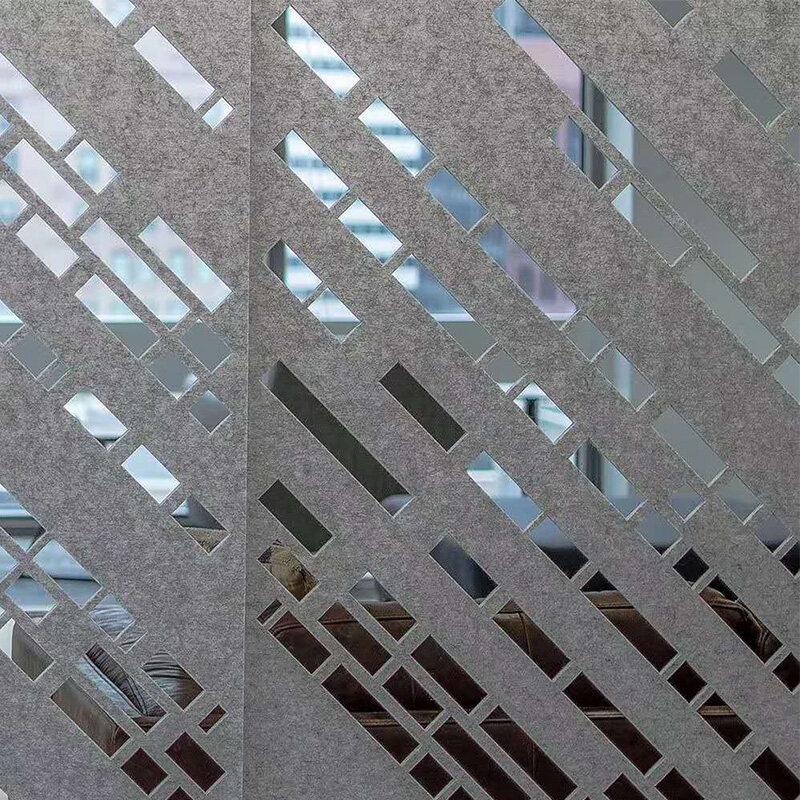

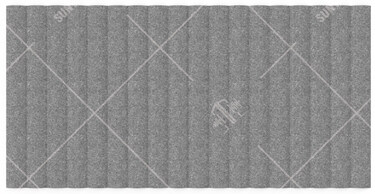

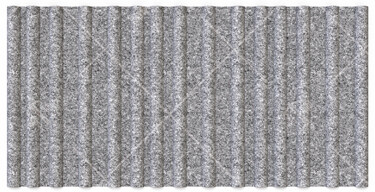

High pressure thermal forming pattern is very similar to the slotted type, but the groove is more smooth looking than the V shape groove, the disadvantage is that the pattern is difficult to customize, followings are some of the standard patterns that we have.

|

|

|

SWave - A

|

SWave - B

|

|

|

|

SWave - C

|

SWave - D

|

Product Characteristics

Thermoformed pet sound-absorbing panels are used to manufacture sound-absorbing panels, which can be used in various environments requiring high performance. Thermoplastic pet sound-absorbing board has excellent sound-absorbing performance, good strength and durability, low thermal conductivity, low fire risk and good surface flatness.

1. Thermoformed pet sound-absorbing board (tc-a) is specially designed for high-temperature areas or long-time work. The soundproof panel can be used in industrial fields, such as hot oil boiler room, gas turbine, shipbuilding and semiconductor industry. The heat shield absorbs heat and secures itself tightly to its structure to protect against high temperatures. It also radiates the absorbed heat to the external environment through its large surface area and transfers it from the high-temperature area. This ensures the reliable performance of the panel in long-term operation and maintains the stable conditions in the machine room.

2. Sound absorbing panels provide complete sound absorption and help reduce reverberation. These panels are lightweight and easy to transport and can be used in a variety of rooms, including music practice rooms, lecture halls or performance stages. These panels consist of 1/8 "thick sound-absorbing foam and a T-shaped back plate, which can be connected to the wall bones to form a solid structure. Each panel can also be hung on any suitable plane with double-sided tape or Velcro tape.

3. Thermoformed sound absorption panel is an economic solution for noise reduction and sound absorption in residential, commercial and industrial environments. These panels are made of an insulating material called polyester, also known as pet, FEP or PTFE. This material is light and easy to operate. It can be attached to a substrate or placed on an existing floor or wall.

4. Sound absorption is essential to reduce unnecessary noise and make your workplace more efficient and comfortable. Thermoplastic pet acoustical panels are an excellent choice for reducing noise in various areas, including production facilities and assembly lines. Our sound-absorbing board is light and easy to install. You can quickly change the environment according to your own needs.

5. Thermoformed pet sound-absorbing board is made of high-performance extruded polyester fiber substrate. The panel is manufactured by extruding the base material between the cold forming tool and the hot forming equipment, so that the panel has a specific shape. The material can be molded into any desired structure as required. Thermoplastic pet sound-absorbing board can be used as partition / furniture panel / interior decoration / bedroom partition / home office partition in living room, office, hotel and other places.

6. Thermoformed pet sound-absorbing board is a sound-absorbing treatment scheme with high cost performance and environmental protection. Its high impact strength allows you to quickly and easily modify the shape of the material and easily adapt to the narrow space of ceilings and walls. The sound absorption effect of such plates is better than that of basic sound-absorbing bricks, which does not mean that they do not need effective sound treatment - they do. This product can be well used as a sound barrier and a means of covering up old or damaged walls.

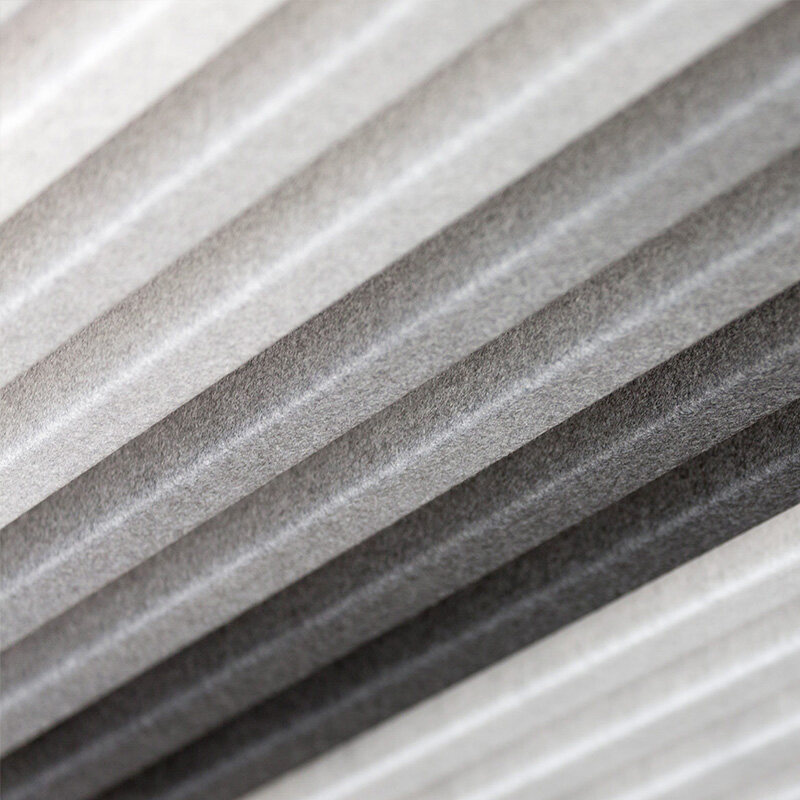

CORE SWATCH

In order to satisfied with the different kinds of requirements from the project, we have wide ranges of colorful choice for you to choose from.

TEST REPORT

ACOUSTIC ABSORPTION COEFFICIENT TEST REPORT ↓

ENVIRONMENTAL FRIENDLY TEST REPORT ↓

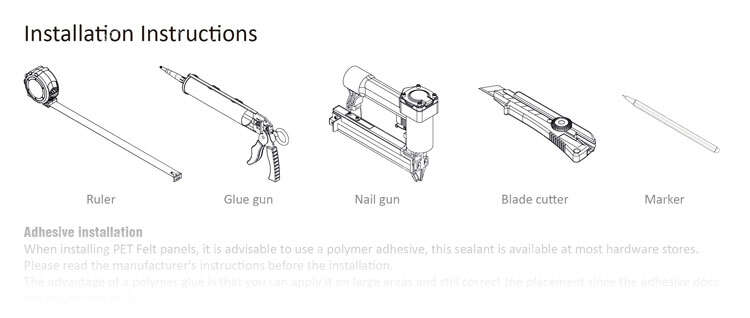

INSTALLATION METHOD

PRODUCT DATA SHEET WITH INSTALLATION INSTRUCTION ↓

FAQ

Q1: What about the lead time?

Usually 9mm and 12mm thickness we have stock, fire retardant treatment needs about 3~5 days, special production requirements need about 3 days.

Q2: Do you have any MOQ limit for acoustic panel order?

Standard thickness 9mm and 12mm do not have MOQ, other thickness will require certain minimum order quantity, please inform your requirement and we will check for you.

Q3: Are you a trading company or a factory?

We produce customzed wooden acoustic panel, operable wall and silent pod only, others are trading, the important things is if we could provide you the same competitive price, quality and good service.

Q4: Sample policy

Free of charge for sample and courier: Only when specific product and project details are available, and drawings that we can analyse for the customized product, free of change for the first time, A4 size sample.

Free of charge for sample: No specific product and project in hands, only interested in having physical samples in hands, we can provide standard sample free of charge, customer should bear the freight cost, customized product will charge extra as well.

CONTACT US

SEND INQUIRY AND REQUEST FOR MORE PRODUCT DETAILS! →